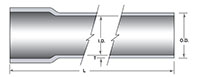

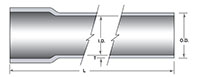

Straight Socket Extra Heavy Wall (XW) Straight Conduits

Straight System

The straight socket system consists of an integral bell and spigot where the bell is bonded on. The spigot end easily slides into the belled end. This joining system is intended for use with Champion Fiberglass epoxy adhesive.

Unit of Measure

| Items |

/Asset/Straight-Socket-Joint-Iron-Pipe-Sizes--IPS--Straight-Conduits.jpg /Asset/Straight-Socket-Joint-Iron-Pipe-Sizes--IPS--Straight-Conduits.jpg 20D-XW-20-S 2 Inch (in) Nominal Size Extra Heavy Wall, Bullet Resistant ID Aboveground Straight Conduit with Straight Socket |

/Asset/Straight-Socket-Joint-Iron-Pipe-Sizes--IPS--Straight-Conduits.jpg /Asset/Straight-Socket-Joint-Iron-Pipe-Sizes--IPS--Straight-Conduits.jpg 15C-XW-20-S 1 1/2 Inch (in) Nominal Size Extra Heavy Wall, Bullet Resistant Iron Pipe Size (IPS) Aboveground Straight Conduit with Straight Socket |

||

| Description | N/A The straight socket system consists of an integral bell and spigot where the bell is bonded on. The spigot end easily slides into the belled end. This joining system is intended for use with Champion Fiberglass epoxy adhesive. | |||

| Brand | N/A Champion Fiberglass®, Inc. | |||

| Type | N/A ID Aboveground Straight Conduit with Straight Socket | N/A Iron Pipe Size (IPS) Aboveground Straight Conduit with Straight Socket | ||

| Nominal Size | N/A 2 in51 mm | N/A 1 1/2 in38 mm | ||

| Wall Thickness | N/A Extra Heavy Wall, Bullet Resistant | |||

| Average Outside Diameter | N/A 2.500 in64 mm | N/A 2.260 in57 mm | ||

| Outside Diameter Tolerance | N/A -0.036 in0.056 in-0.9 mm1.4 mm | |||

| Inside Diameter [Min] | N/A 2.000 in51 mm | N/A 1.760 in45 mm | ||

| Nominal Wall Thickness1 | N/A 0.25 in6 mm | |||

| Length (L) | N/A 20 ft6.1 m | |||

| Color | N/A Black | |||

| End Type | N/A Bell End | |||

| Weight | N/A 1.26 lb/ft1.88 kg/m | N/A 1.18 lb/ft1.76 kg/m | ||

| Industry Standards/Certifications | N/A Underwriters Laboratories (UL), Canadian Standards Association (CSA) | |||

| Application | N/A Highest level of physical protection, Class 1 Div 2 & Class 1 Zone 2 Applications | |||

| Features | N/A | N/A Most Commonly used. | ||

| General Information |

N/A

Fiberglass Conduit Specifications for Use Below Ground The conduit shall be fiberglass conduit, also known as Reinforced Thermosetting Resin Conduit (RTRC), manufactured using the single circuit filament winding process. Multi circuit windings are not allowed. The conduit shall have a winding angle as close as possible to 54.75 degrees. The resin system shall be epoxy based, with no fillers, using an anhydride curing agent. The fiberglass shall consist of continuous E-glass roving. The conduit shall not contain any halogen compounds containing chlorine, bromine, fluorine and iodine in more than trace amounts when burning. Conduit and elbows shall be manufactured from the same resin/hardener/glass systems manufactured by the same filament wound system. Fiberglass conduit fittings and accessories shall be manufactured using one of two manufacturing procedures. The first method shall use the same process, methods, and components as used to manufacture the fiberglass conduit. The second method shall use the compression molding process, Sheet Molding Compound (SMC), for the manufacture of the finished component. The SMC material shall be a vinyl ester resin with +30% reinforcement of glass. The glass fibers should be approximately 1" in length. The SMC material shall be fire resistant to UL 2515. Conduit shall be integral bell and spigot or bonded coupling and spigot. Conduit, elbows and fittings are specified for use throughout a temperature range of -60ºF (-51ºC) to 250ºF (121ºC). Manufacturer shall have a current Certificate of Compliance, issued by an independent and accredited company, with an ISO 9001:2008 Quality Management System. |

|||

|

||||