-

Fusion Splice Protection

fusion-splice-protection

-

Colonial Teltek Fusion Splice Trays

Colonial Teltek Fusion Splice Trays are aluminum with a black powder coated finish and clear plastic cover. The tray is designed to hold up to 24 fibers and is universal to fit in most splice housing units.

-

Keptel Splice Trays

Keptel Splice Trays are equipped for 24 fusion splice organizing. Trays are black plastic with clear covers.

-

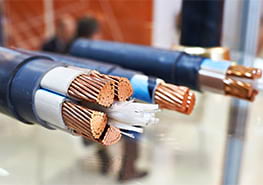

Single/Ribbon Fiber Sleeves

The single and ribbon fiber splice protection sleeves are made with a stainless steel strength member, polyolefin copolymer inner tube and polyolefin outer tube. The single fiber sleeve is specifically constructed with a 320 stainless steel with rounded and polished ends. The ribbon fiber sleeves are manufactured with polished quartz and polyethermide. The sleeves are the industry's highest quality and are heat bonded to ensure that the tubes maintain perfect alignment during shipping, handling and shrinking.

-

Ultra Sleeves

Ultra Sleeves

(2)The Ultra Sleeve is a high performance, easy to install fiber optic fusion splice protection cover that requires no heat shrink, curing, crimping or gluing. The plastic housing comprises of two halves that fold along a hinge and is delivered in an open position, ready for fused fibers to be placed into the sleeve. Once the fibers are in the protection cover, the sleeve closes and locks, preventing the ultra sleeve from being used again. The locks on the sleeve are what keeps the protection cover from opening, and compresses the acrylic foam to provide a hermetic seal.

-

Ultra Splices

Ultra Splices

(2)The Ultra Splice has a glass reinforced Liquid Crystal Polymer (LCP) plastic housing with outside dimensions of 40 mm in length and 5.7 mm in diameter (max). The splices are individually packaged and have a weight of 0.86 grams each. Average splicing loss is less than 0.2dB and is tunable for minimum loss. Mean loss is less than 0.07dB and is tunable for minimum loss. Back reflection (return loss) is -50dB, and loss variation during thermal cycling (-40 to +80 ºC) is less than 0.1dB. One splice accepts any combination from 250-900 microns for coating (buffer size), and fiber retention is greater than 1250 grams. Installation time is 30 to 45 seconds after fiber preparation.